Lean methodology is a systematic approach to identifying and eliminating waste in business processes. It is focused on delivering maximum value to the customer through the most efficient use of resources.

Lean principles can be applied to any industry to streamline operations and improve productivity.

This guide provides an overview of lean methodology and actionable steps for implementing it in your workplace.

Supercharge Your Training Courses – A Special Offer From Oak Innovation

What is Lean Methodology?

Lean methodology originated in manufacturing, but its principles can be extended to any business process.

The core idea is to maximize customer value while minimizing waste. Waste is any activity or process that consumes resources without creating value for the customer.

The main elements of lean methodology include:

- Identifying value from the customer’s perspective.

- Mapping the value stream and eliminating waste.

- Achieving flow in processes.

- Responding to customer pull.

- Pursuing perfection through continuous improvement.

Key Features of a Lean Methodology

Some key features of a lean methodology include:

- Focus on the customer – Define value from the customer’s perspective. Align processes to deliver maximum value.

- Identify and eliminate waste – Target non-value-adding activities for removal.

- Continuous improvement – Continually refine and optimize processes.

- Workload leveling – Smooth out workflow to reduce bottlenecks.

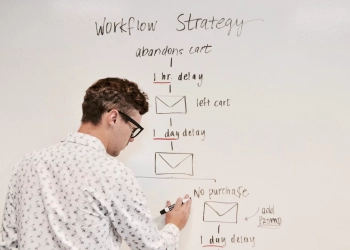

- Visual management – Use visual systems to control inventory, schedule work, highlight problems, etc.

- Standardized work – Document procedures to maintain consistency.

- Teamwork and communication – Engage staff at all levels to share ideas and solve problems.

Benefits of Implementing Lean

Adopting lean principles provides many benefits, including:

- Increased productivity and efficiency.

- Improved quality.

- Reduced costs.

- Enhanced customer satisfaction and sales.

- Greater flexibility and responsiveness.

- Engaged and empowered employees.

Steps for Implementing Lean

The key steps involved in implementing lean methodology are:

- Identify customer value – Determine what the customer finds valuable in your products/services.

- Map the value stream – Document the steps involved in your processes so you can identify waste.

- Remove waste – Eliminate activities that don’t contribute value based on the value stream map.

- Implement flow – Organize process steps to maximize flow and reduce interruptions.

- Adopt pull scheduling – Produce based on actual customer demand rather than forecasts.

- Strive for perfection – Continuously look for small ways to improve and eliminate waste.

- Standardize processes – Document procedures so improvements can be sustained.

- Engage employees – Motivate staff to share lean ideas and participate in kaizen events.

- Provide lean training – Educate employees on lean principles and tools.

- Review metrics – Track key performance indicators to quantify improvements.

Best Practices for Lean Methodology

Some best practices to keep in mind when implementing lean include:

- Seek input from frontline employees.

- Start with pilot projects before broader implementation.

- Use visual metrics to track performance.

- Design processes to enhance flexibility.

- Cross-train employees (e.g., sales methodologies) to increase workforce agility.

- Encourage bottom-up innovation and problem-solving.

- Foster an environment of continuous experimentation.

- Align policies and procedures to support lean practices.

- Reward and recognize employees for lean accomplishments.

Examples of Lean in Action

Here are a few examples of how lean principles have been applied by companies:

- Toyota uses Kanban cards to signal when more inventory is needed in its just-in-time system. This aligns production with actual demand.

- Apple stores enable customers to check out anywhere in the store with mobile devices, eliminating the waste of waiting in line.

- Amazon has implemented extensive automation in its fulfillment centers to optimize picking and packing processes.

- Spotify uses agile methodologies and software development methods with small cross-functional teams to frequently deliver new features.

- Nike applies lean manufacturing techniques to their apparel production to minimize defects and speed up changeovers.

Conclusion

Implementing lean methodology requires a company-wide commitment to eliminating waste and continuous improvement.

Lean principles can dramatically increase productivity, quality, and customer satisfaction when applied systematically.

Lean success hinges on engaging employees at all levels to help identify and solve problems.

With the proper training and leadership support, organizations can leverage lean to gain a competitive advantage.

We encourage you to explore our corporate, employee, and leadership training course materials.