Failure mode and effects analysis (FMEA) is a systematic technique for identifying potential failures in designs, processes, and services before they reach the customer.

FMEA helps organizations prevent defects, reduce costs, and improve safety and customer satisfaction.

This guide will provide an overview of FMEA, key definitions, background information, the FMEA process, and creative examples of how FMEA is applied in various industries.

Definitions

- Failure mode: How a process could potentially fail to meet requirements.

- Failure effect: The result of a failure mode on the operation, function, or status of a process/product.

- Severity: The seriousness of the failure effect.

- Occurrence: The probability that the specific cause of the failure mode will occur.

- Detection: The probability that the failure mode will be detected before the product reaches the customer.

Background on Failure Mode and Effects Analysis (FMEA)

FMEA was initially developed in the 1950s by the aerospace industry and further refined by the automotive industry.

It helps identify potential failure modes based on experience and engineering knowledge.

Teams use FMEA to methodically analyze designs, manufacturing and assembly processes, maintenance procedures, and more.

The goal is to prevent failures before they reach the customer and to prioritize quality improvement efforts (stack ranking, conflict mode instruments).

Some key benefits of FMEA include:

- Improved product quality and reliability.

- Reduced costs by preventing defects.

- Enhanced customer satisfaction.

- Early identification of potential failure modes.

- Prioritization of quality improvements.

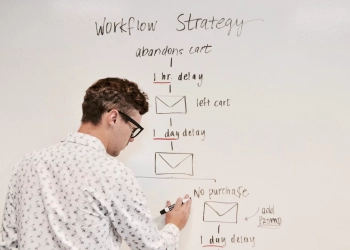

The FMEA Process: 8 Key Steps

Conducting an effective FMEA involves the following eight main steps:

1. Select the design, process, or service to analyze

Clearly define the scope of the FMEA. Focus on high-risk areas that have caused problems in the past.

Special Offer – Course Packs Only $10.00 Each

2. Assemble the cross-functional team

Include team members from engineering, manufacturing, quality, sales, and other relevant departments.

3. Identify failure modes and their effects

Brainstorm potential failure modes and describe the effects on the customer if each failure occurred.

4. Rank the severity of failure effects

Assess the seriousness of each effect and assign a severity ranking (typically 1-10).

5. Identify causes and rank occurrence

Determine potential causes for each failure mode and rank the probability of occurrence (typically 1-10).

6. Identify current controls and rank detection

Describe existing process controls and rank the probability of detection (typically 1-10).

7. Calculate the risk priority number (RPN)

Multiply the severity, occurrence, and detection rankings to obtain the RPN for each failure mode.

8. Develop and implement actions to address high-risk failures

Reduce severity, occurrence, or detection rankings for high-priority modes.

10 Examples of Failure Mode and Effects Analysis (FMEA)

Here are ten examples of how FMEA is applied across various industries:

Automotive: Analyze potential failure modes in new car engine designs.

Aerospace: Identify possible failures in aircraft hydraulic systems.

Medical: Detect failure modes in MRI machine calibration processes.

Manufacturing: Pinpoint defects in circuit board soldering processes.

Oil and Gas: Evaluate failure modes in offshore oil rig equipment.

Power: Assess failure modes in nuclear power plant backup systems.

Food: Identify potential food packaging flaws and contamination.

Pharmaceutical: Analyze drug production processes for possible failures.

Software: Find bugs and defects in new software applications.

Supply Chain: Detect failures in inventory management and logistics.

To discover more about how our training course materials can help you to increase learner engagement, provide effective training courses, and extend your team’s knowledge, please take a moment to review our frequently asked questions, special offers, and training course material.