Are you looking to create a safer work environment and reduce the risk of injuries?

If so, you need to consider sourcing a comprehensive manual handling workshop to equip your team with the knowledge and skills they need to handle loads safely and efficiently.

What Teams Will Learn

By the end of a comprehensive manual handling health and safety training workshop, participants will:

1. Recognize Workplace Hazards: Be aware of potential dangers in your working environment.

2. Understand Spinal Health: Learn about the structure of the spine and the risks associated with improper lifting techniques.

3. Assess Before You Lift: Develop the ability to evaluate a load and plan the safest approach for lifting.

4. Master Multiple Techniques: Acquire knowledge of four different lifting techniques suitable for various situations.

5. Hands-On Practice: Practice all four lifting techniques in a controlled, safe environment.

Why This Matters

Manual handling injuries account for a significant portion of workplace accidents.

By investing in proper training, you’re not just complying with regulations – you’re actively protecting your most valuable asset: your people.

Who Should Attend

A manual handling workshop is ideal for anyone whose job involves lifting, carrying, pushing, or pulling loads, regardless of the industry. Everyone can benefit from these essential skills, from warehouse workers to office employees.

Don’t let preventable injuries impact your workforce. Empower your team with the knowledge they need to stay safe.

We recommend that you look to book a Manual Handling Workshop today from your local provider and take the first step towards a safer, more efficient workplace!

To assist you, let’s dive deeper into the five common learning objectives that a manual handling training course should follow.

1. Recognize Workplace Hazards: Workplace hazards are crucial for maintaining a safe and healthy work environment. There are several types of hazards that employees and employers should be aware of:

Types of Workplace Hazards

Physical Hazards

These include safety risks such as slips, trips, and falls, the single most significant cause of work-related injury, accounting for 29% of workplace injuries in the UK. Other physical hazards involve working at heights, operating dangerous machinery, and electrical hazards.

Chemical Hazards

These threats primarily affect employees exposed to dangerous liquids, solvents, or flammable gases. Workers in cleaning facilities, engineers, and those in field-based roles are most at risk.

Biological Hazards

These hazards involve exposure to dangerous substances and diseases associated with working among animals, people, or infectious plant materials. Healthcare workers, laboratory technicians, and outdoor workers are particularly vulnerable.

Ergonomic Hazards

These occur when work conditions put a strain on the body. Examples include improperly adjusted workstations, frequent lifting, poor posture, and repetitive movements.

Psychosocial Hazards

Also known as workload hazards, it includes issues that could cause stress or strain, such as excessive workload, violence, or aggression.

Environmental Hazards

These affect workers exposed to extreme weather conditions, continuous loud noise, radiation, or harmful UV rays.

Identifying Workplace Hazards

To effectively recognize workplace hazards:

1. Form a hazard identification team with diverse perspectives.

2. Review existing safety documentation, including incident reports and risk assessments.

3. Conduct regular workplace walkthroughs to inspect work areas, equipment, and processes physically.

4. Observe employees’ tasks and interactions to spot risks that may not be immediately apparent.

5. Encourage employees to participate actively in hazard identification and reporting.

6. Review accidents and near-miss logs to investigate root causes and program shortcomings.

By systematically identifying and addressing these hazards, organizations can create a safer work environment and reduce the risk of workplace injuries and illnesses.

2. Understand Spinal Health:

Understanding spinal health is crucial for maintaining overall well-being and preventing injuries. The spine, also known as the vertebral column, is a complex structure that plays a vital role in our body’s function and movement. Make sure always to seek proper professional advice.

Structure of the Spine

The human spine typically consists of 33 vertebrae:

– 7 cervical vertebrae (C1-C7) in the neck

– 12 thoracic vertebrae (T1-T12) in the upper back

– 5 lumbar vertebrae (L1-L5) in the lower back

– 5 sacral vertebrae (fused)

– 4 coccygeal vertebrae (fused)

The upper 24 vertebrae are articulating and separated by intervertebral discs, while the lower nine are typically fused in adults.

Functions of the Spine

The spine serves several critical functions:

1. Protection: It houses and protects the spinal cord and nerves.

2. Structural Support: The spine forms the body’s central axis, supporting the head and transferring weight to the legs.

3. Flexibility: Its unique joint structure allows for rotation and bending.

4. Attachment Site: It provides ribs and various muscle attachment points.

Spinal Health Considerations

Intervertebral Discs

These structures cushion between vertebrae, acting as shock absorbers and allowing spinal flexibility. Maintaining disc health is crucial for overall spinal function.

Spinal Curvature

The spine has natural curves that help distribute weight and maintain balance. Abnormal curvatures can lead to conditions like scoliosis.

Muscles and Ligaments

Numerous muscles and ligaments support the spine, including the anterior and posterior longitudinal ligaments. Keeping these structures strong and flexible is essential for spinal health.

Potential Spine Issues

Various conditions can affect spinal health, including:

– Herniated discs

– Spinal stenosis

– Degenerative disc disease

– Spondylolisthesis

– Fractures

Understanding the spine’s anatomy and function is crucial for maintaining proper posture, lifting techniques, and overall spinal health. This can help prevent these issues and promote a healthy, pain-free back.

3. Assess Before You Lift:

Assessing before you lift is a crucial step in preventing manual handling injuries.

This process involves evaluating the load and the surrounding environment to ensure safe lifting practices.

Here’s how to properly assess a lift:

Task Evaluation

Before attempting to lift, consider the following aspects of the task:

– Frequency of the lift

– Distance the load needs to be moved

– Height of the lift (from floor to destination)

– Any twisting or awkward postures required

Load Assessment

Examine the load itself:

– Weight of the object

– Size and shape

– Stability and balance

– Presence of handles or gripping points

Environmental Factors

Assess the area where the lift will take place:

– Available space for movement

– Floor conditions (slippery, uneven)

– Lighting adequacy

– Temperature and ventilation

Individual Capability

Consider your physical ability:

– Strength and fitness level

– Any pre-existing medical conditions

– Familiarity with proper lifting techniques

Risk Identification

Look for potential hazards:

– Obstacles in the path

– Need for sudden movements

– Uneven weight distribution

– Carrying over long distances

By thoroughly assessing these factors before lifting, you can identify potential risks and take appropriate measures to ensure a safe lift.

This may include using mechanical aids, breaking the load into smaller parts, or seeking colleague assistance.

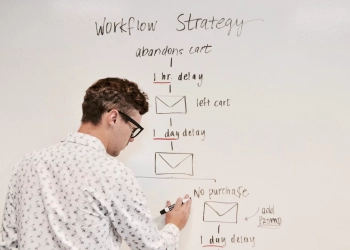

4. Master Multiple Techniques:

When it comes to manual handling, mastering multiple lifting techniques is crucial for workplace safety.

Here are four different lifting techniques that workers should know and practice:

Basic Diagonal Lifting Technique

This technique is suitable for small objects when you can straddle the load:

1. Stand close to the object with a wide stance, one foot forward.

2. Keep your back straight and use your legs to lower yourself.

3. Grasp the object at opposite corners.

4. Lift slowly, following your head and shoulders, keeping the load close to your body.

Power Zone Lifting

This method focuses on lifting within the area between mid-thigh and mid-chest:

1. Keep the object in the “power zone” where you can lift the most with the least effort.

2. Position the load close to your body.

3. Use your leg muscles to lift, keeping your back slightly arched.

Team Lifting

For heavier or awkward loads:

1. Coordinate with your partner before lifting.

2. Lift simultaneously using proper techniques.

3. Communicate throughout the lift to ensure synchronization.

Push-Pull Technique

When possible, push or pull instead of lifting:

1. Use mechanical aids like hand trucks or pushcarts.

2. Push rather than pull, allowing you to use your body weight.

3. Keep the load close and lock your arms when pushing.

Remember, regardless of the technique used, continually assess the load and your environment before lifting. Plan your route, ensure a clear path, and never attempt to lift more than you can safely manage.

5. Hands-On Practice In Manual Handling Training:

Hands-on practice is vital to manual handling training, ensuring that participants understand the theory and apply it in real-world scenarios.

Here’s how practical exercises can enhance learning and safety:

Benefits of Hands-On Practice

1. Skill Reinforcement: Practical sessions allow participants to apply lifting techniques, reinforcing theoretical knowledge.

2. Muscle Memory: Repeated practice helps develop muscle memory, making safe handling techniques second nature.

3. Immediate Feedback: Instructors can correct improper techniques on the spot, reducing the risk of injury.

4. Confidence Building: Practicing in a controlled environment boosts confidence in handling loads safely.

Key Components of Hands-On Practice

1. Warm-Up Exercises:

– Incorporate stretches like hamstring and hip flexor stretches to prepare muscles for activity.

– Perform strength-building exercises such as squats and planks to enhance core stability and leg strength.

2. Practice Lifting Techniques:

– Use different objects to simulate workplace loads.

– Demonstrate and practice techniques like diagonal lifting, power zone, and team lifting.

3. Simulated Scenarios:

– Replicate workplace-specific tasks such as pushing, pulling, or carrying loads.

– Include environmental challenges like narrow spaces or uneven surfaces for realistic practice.

4. Risk Assessment Application:

– Teach participants to assess their load, environment, and physical capacity before lifting.

– Encourage them to identify hazards and adapt their approach accordingly.

Practical Tips for Success

– Use Appropriate Equipment: Provide tools like trolleys or straps for practicing assisted handling.

– Encourage Teamwork: Include team lifting exercises to promote coordination and communication.

– Monitor Progress: Offer feedback during practice sessions to maintain proper technique.

Hands-on practice ensures that employees are well-prepared to handle manual tasks safely in their workplaces.

By combining theoretical knowledge with practical application, organizations can significantly reduce the risk of injuries while fostering a culture of safety and efficiency.

Why Manual Handling Training Is So Important.

Manual handling training is essential for ensuring workplace safety and preventing injuries.

Here’s why it matters:

1. Prevention of Injuries: Manual handling tasks, such as lifting, pushing, pulling, or carrying loads, are a leading cause of workplace injuries. These include musculoskeletal disorders (MSDs), back pain, and strains, which can result from improper techniques or repetitive actions. Training equips employees with the skills to handle loads safely, reducing the risk of short-term and long-term injuries.

2. Compliance with Legal Requirements: To illustrate, employers must protect workers from hazardous manual handling under regulations like the UK’s Manual Handling Operations Regulations 1992. Proper training ensures compliance with these laws, minimizing liability and fostering a safety culture. We encourage you to seek professional medical and legal advice concerning legislation in your location.

3. Increased Productivity: A safer workplace leads to fewer injuries, reduces absenteeism, and maintains workforce efficiency. Employees trained in manual handling can perform tasks more effectively, contributing to a more productive environment.

4. Enhanced Awareness of Risks: Training helps employees recognize hazards associated with manual handling tasks, such as awkward loads, poor posture, or unsafe environments. This awareness enables them to assess risks and take preventive measures before engaging in tasks.

5. Improved Mental and Physical Well-Being: By reducing the risk of physical injuries, manual handling training also helps prevent mental health challenges from living with chronic pain or injury-related stress.

Investing in manual handling training is a legal obligation and a proactive step toward protecting employees’ health and well-being while enhancing workplace safety and efficiency.

Please Note: Oak Innovation accepts no responsibility for injuries caused by this information. We provide this information to help you gauge what should be included in your manual handling workshops. Please follow the advice carefully and ensure that staff are always supervised. By investing in proper training, you’re not just complying with regulations – you’re actively protecting your most valuable asset: your people. We recommend that you look to book a Manual Handling Workshop today from your local provider and take the first step towards a safer, more efficient workplace! We also recommend that you always get specialist advice on the safety of your staff.