Practical problem-solving is crucial for organizations to thrive.

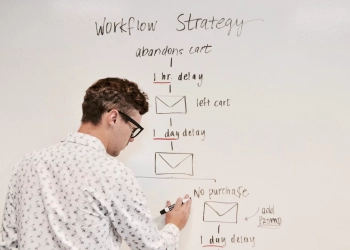

The 8D problem-solving method systematically helps teams identify, analyze, and resolve complex problems.

This guide will provide an overview of the 8D problem-solving method within corporate learning and problem-solving, including its definition, best practices, features, pros and cons, benefits, and examples.

Supercharge Your Training Courses – A Special Offer From Oak Innovation

Definition

The 8D problem-solving method, or the Eight Disciplines, is a structured approach to systematically addressing and resolving problems.

The Ford Motor Company initially developed it and has since been widely adopted across various industries.

The method consists of eight steps that guide teams through problem-solving, ensuring a thorough analysis and effective resolution.

Best Practices

To effectively implement the 8D problem-solving method within corporate learning and problem-solving, consider the following best practices:

- Cross-functional teams: Form diverse teams with representatives from different departments or areas of expertise. This ensures a comprehensive understanding of the problem and encourages collaboration.

- Clear problem statement: Define the problem and its impact on the organization. This helps focus the team’s efforts and ensures everyone is aligned on the issue.

- Data-driven analysis: Gather relevant data and facts to analyze the problem objectively. Utilize tools such as root cause analysis, fishbone diagrams, and Pareto charts to identify the underlying causes.

- Systematic approach: Follow the eight disciplines of the 8D problem-solving method sequentially. Each step builds upon the previous one, ensuring a thorough and structured approach to problem-solving.

- Effective communication: Maintain open and transparent communication between the team and stakeholders. Regularly update all involved parties on the progress, findings, and proposed solutions.

- Continuous improvement: Encourage a culture of continuous improvement and the promotion of employee training courses by documenting lessons learned and implementing preventive measures to avoid similar problems in the future.

Features

The 8D problem-solving method encompasses the following key features:

- Structured approach: The method provides a step-by-step framework that guides teams through problem-solving, ensuring a systematic and comprehensive analysis.

- Team collaboration: The method encourages cross-functional collaboration, bringing together individuals with diverse perspectives and expertise to solve the problem collectively.

- Root cause analysis: The 8D method emphasizes identifying and addressing the root causes of the problem rather than merely treating the symptoms. This helps prevent the issue from recurrence.

- Data-driven decision-making: This method uses data and facts to drive the problem-solving process, ensuring objective analysis and informed decision-making.

Pros and Cons

Pros of using the 8D problem-solving method within corporate learning and problem-solving include:

- Provides a structured and systematic approach to problem-solving.

- Encourages collaboration and cross-functional teamwork.

- Focuses on identifying and addressing root causes.

- Promotes data-driven decision-making.

- Facilitates continuous improvement and learning.

Cons of using the 8D problem-solving method include:

- It requires time and resources to implement effectively.

- It may not be suitable for simple problems.

- It relies on accurate data and information, which may not always be readily available.

Benefits

Implementing the 8D problem-solving method within corporate learning and problem-solving can yield several benefits, including:

- Improved problem-solving capabilities: The method equips teams with a structured approach and tools to analyze and resolve complex problems effectively.

- Enhanced collaboration: The method promotes collaboration and knowledge sharing by involving cross-functional teams, leading to innovative solutions.

- Preventive measures: Emphasizing root cause analysis helps identify and address underlying issues, reducing the likelihood of problem recurrence.

- Data-driven decision-making: The method encourages the use of data and facts, enabling informed decision-making and reducing reliance on subjective opinions.

Example

Let’s consider an example to illustrate the application of the 8D problem-solving method:

Problem: A manufacturing company is experiencing a high defect rate in one of its product lines, resulting in customer complaints and increased costs.

- D1: Form a team: Assemble a cross-functional team of representatives from production, quality control, and engineering.

- D2: Define the problem: Define the issue, including the specific product line, defect types, and their impact on customers and costs.

- D3: Containment actions: Implement immediate actions to contain the problem, such as segregating defective products and halting production.

- D4: Root cause analysis: Use tools like fishbone diagrams and Pareto charts to identify potential root causes. Analyze data and conduct investigations to narrow down the causes.

- D5: Corrective actions: Develop and implement corrective actions to address the identified root causes. This may involve process changes, equipment upgrades, or training programs.

- D6: Preventive actions: Implement preventive measures to avoid similar problems in the future. This may include updating standard operating procedures, conducting regular audits, or enhancing training programs.

- D7: Verify effectiveness: Monitor and measure the effectiveness of the corrective and preventive actions implemented. Use data and feedback to validate the improvements.

- D8: Standardize and share: Document the problem-solving process, including the findings, actions taken, and lessons learned. Share this knowledge across the organization to facilitate learning and continuous improvement.

By following the 8D problem-solving method, the manufacturing company can systematically address the high defect rate, reduce customer complaints, and improve overall product quality.

Conclusion

The 8D problem-solving method is a valuable tool within corporate learning and problem-solving.

It enables organizations to effectively address complex problems and drive continuous improvement by providing a structured approach, promoting collaboration, and emphasizing root cause analysis.

By implementing the best practices outlined in this guide, organizations can harness the benefits of the 8D method and enhance their problem-solving capabilities.